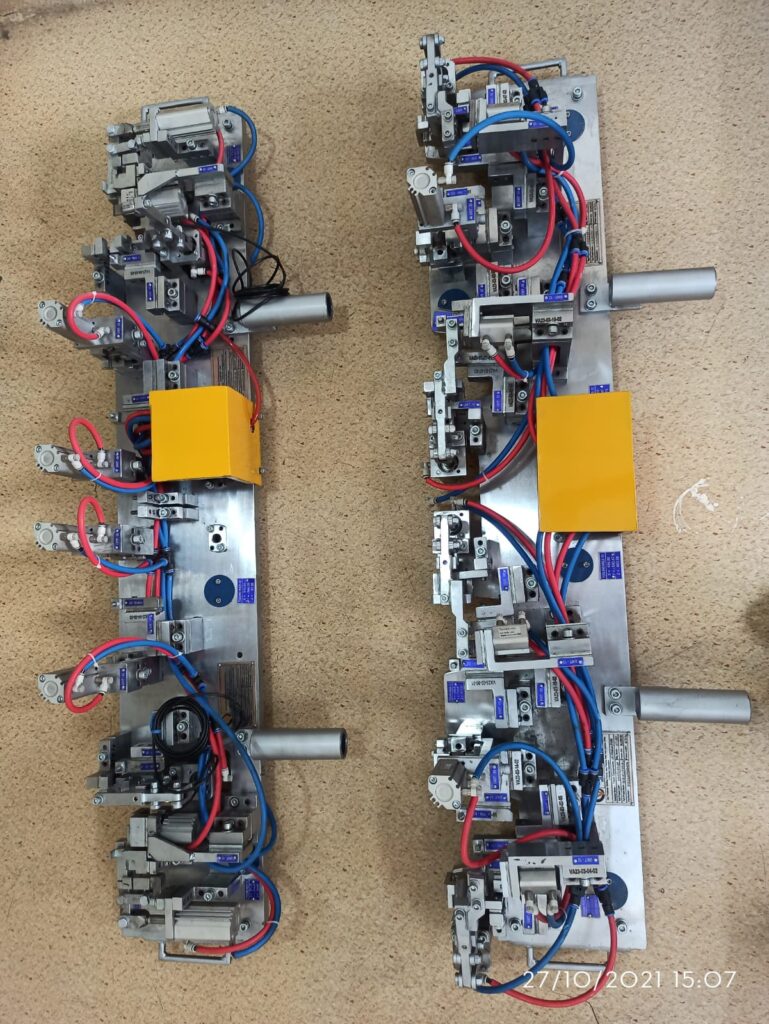

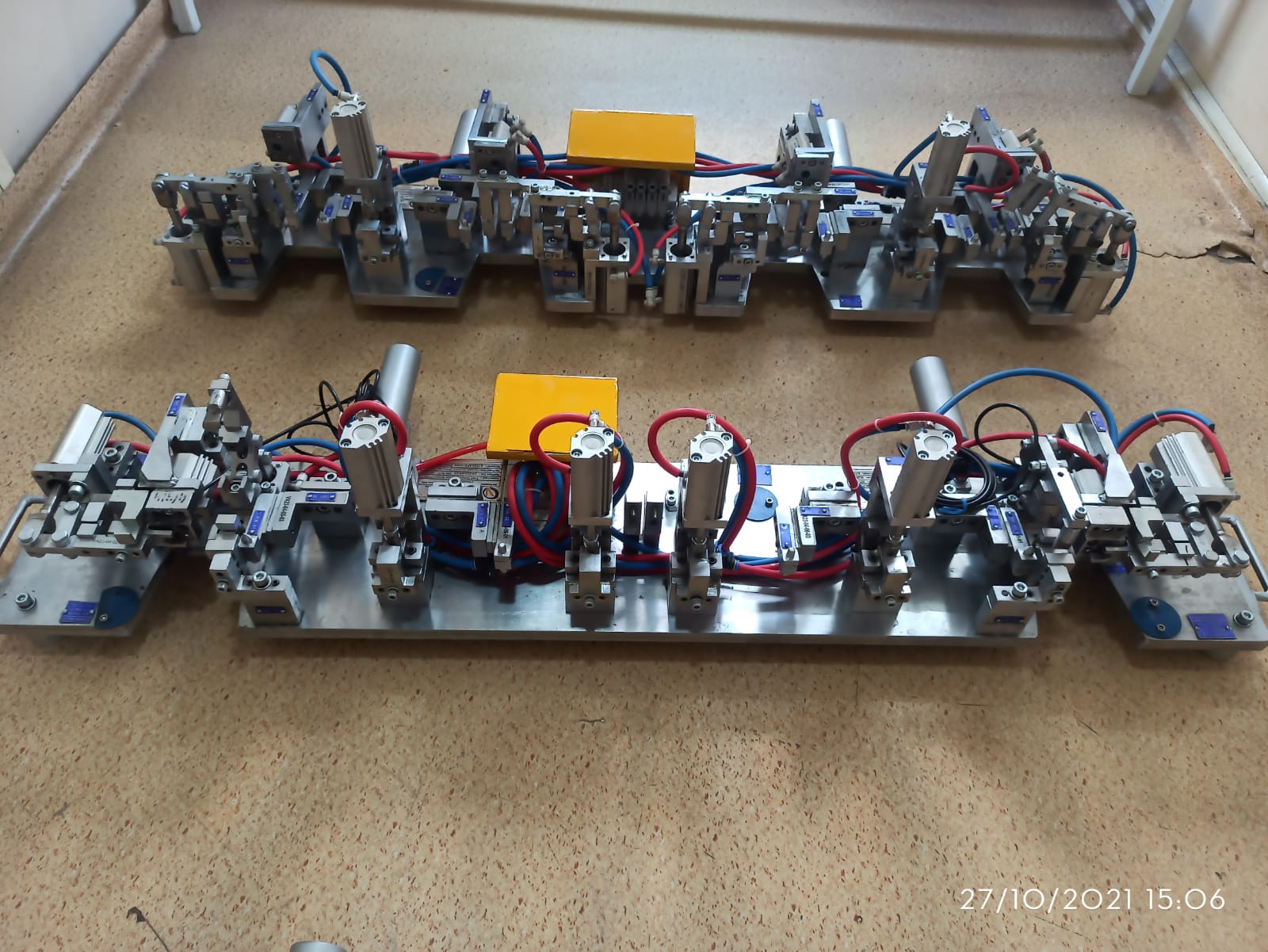

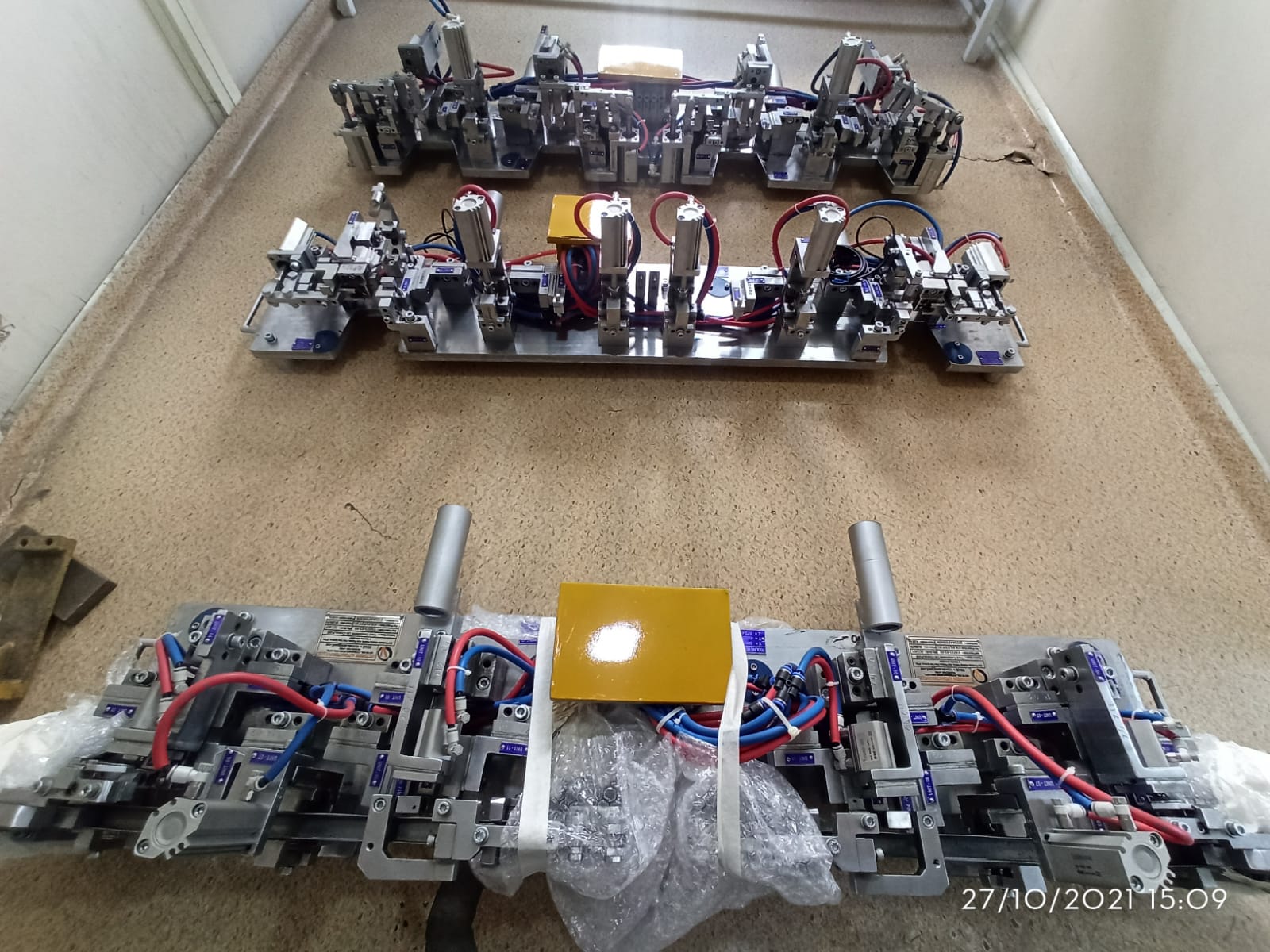

SPM AND WELDING FIXTURES

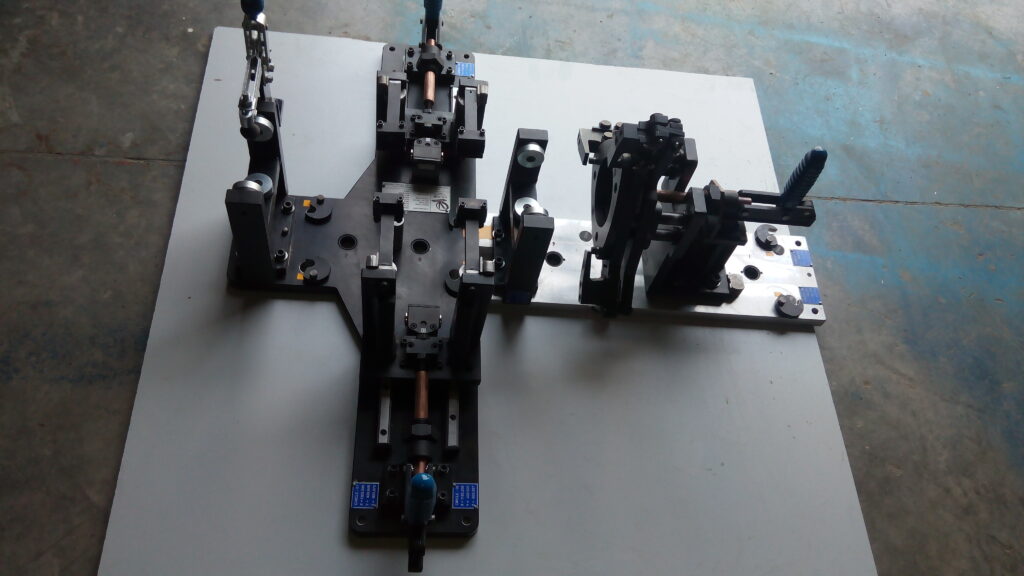

PHOTOMETRY FIXTURES

Photometry checking fixtures are specialized fixtures designed to hold and position lighting components or assemblies accurately during photometric testing. Photometric testing measures the intensity, distribution, direction, and quality of light emitted from automotive lighting parts such as headlamps, tail lamps, or signal lights, ensuring they meet industry standards and specifications.

These fixtures ensure repeatability and precision in tests that evaluate light performance as per regulatory and OEM requirements, often used in quality control and product development in the automotive sector. They allow secure, consistent positioning of parts for measurement with photometric equipment. Manufacturers of photometry fixtures typically emphasize accuracy, durability, user-friendliness, and compliance with certifications such as ISO 9001 to support high-quality inspection processes. These fixtures form a crucial part of testing systems designed to verify lighting components’ functionality and safety before assembly or shipment.

In summary, photometry checking fixtures are precision devices used to hold automotive lighting parts in place during detailed light measurement testing to validate their performance and compliance.