SHEET METAL PANEL CHECKING FIXTURES

SHEET METAL PANEL CHECKING FIXTURES

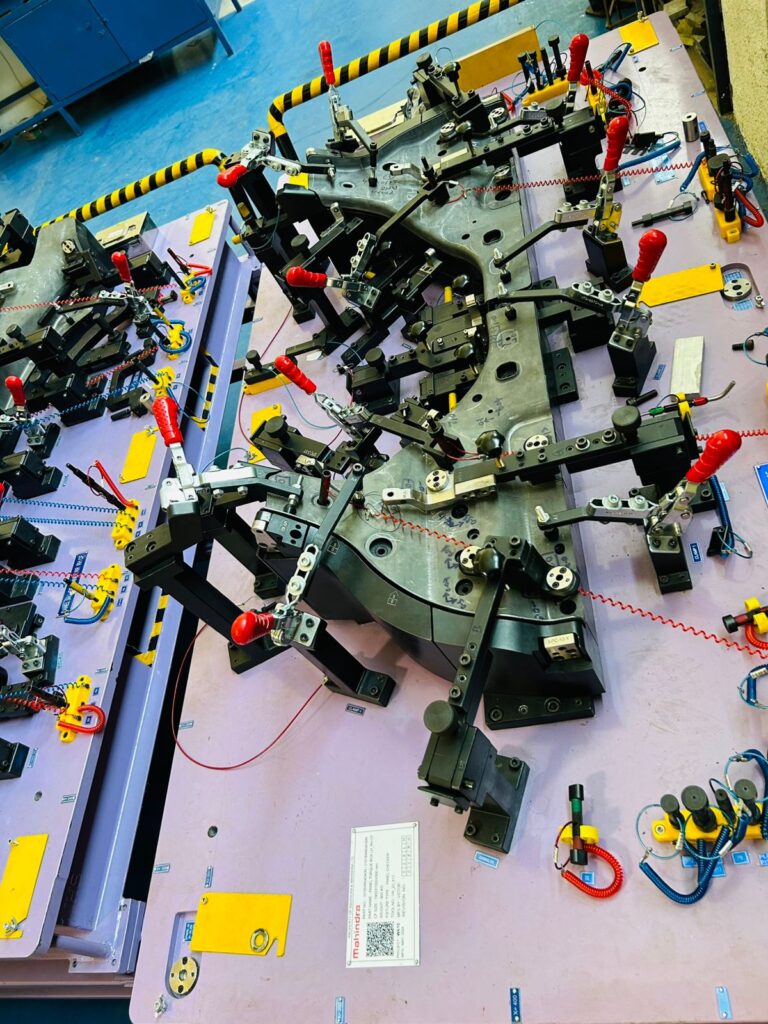

Sheet metal panel checking fixtures are precision tools used in manufacturing to verify the dimensional accuracy, alignment, and quality of sheet metal panels, especially in the automotive industry. These fixtures hold the sheet metal parts securely in place to inspect features such as shape, size, hole positions, bends, flushness, and gaps, ensuring they conform to design specifications and tolerances.

Key purposes of sheet metal panel checking fixtures include:

- Verifying dimensional accuracy and geometric conformity

- Ensuring assembly compatibility of sheet metal components

- Supporting quality control by detecting deviations or defects early

- Enabling consistent and repeatable inspections, often used with coordinate measuring machines (CMM)

Materials commonly used for these fixtures include aluminum, steel, or other wear-resistant alloys to maintain precision and durability. Some fixtures are adjustable to accommodate variations in parts and may be integrated with automated inspection systems for efficiency.

These fixtures may be custom-designed based on the specific sheet metal panel, with features such as clamps, pins, and locators that precisely hold the panel during inspection. Production companies in Pune and across India manufacture a wide range of these fixtures tailored to customers’ specifications, ensuring compliance with international quality standards.