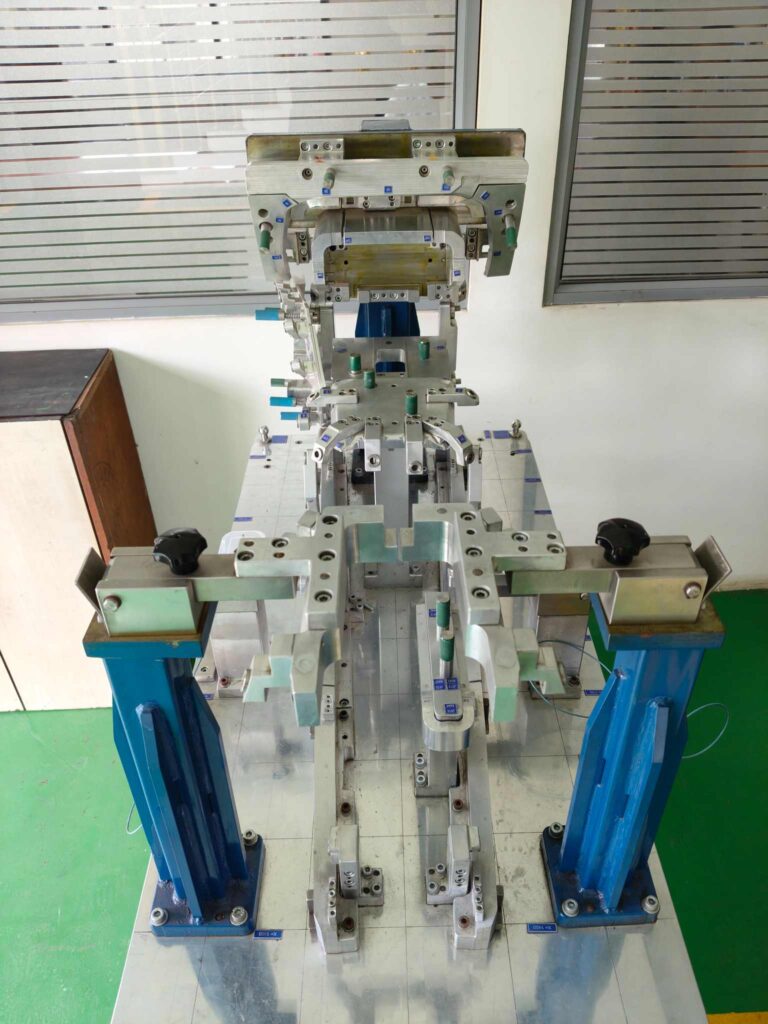

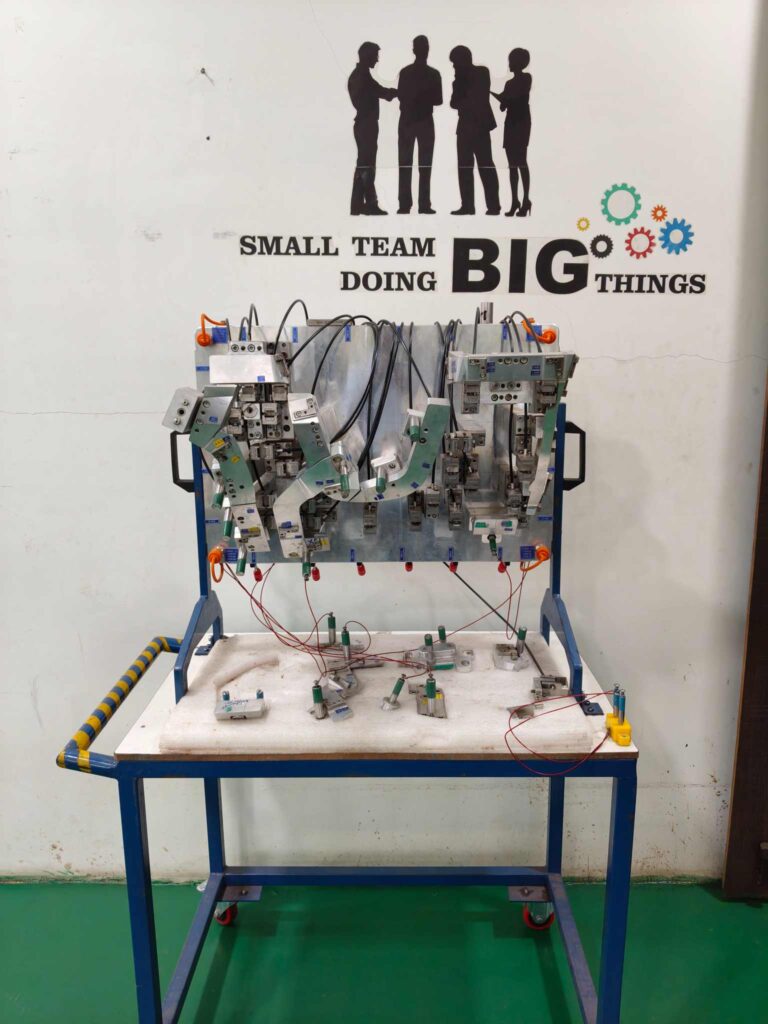

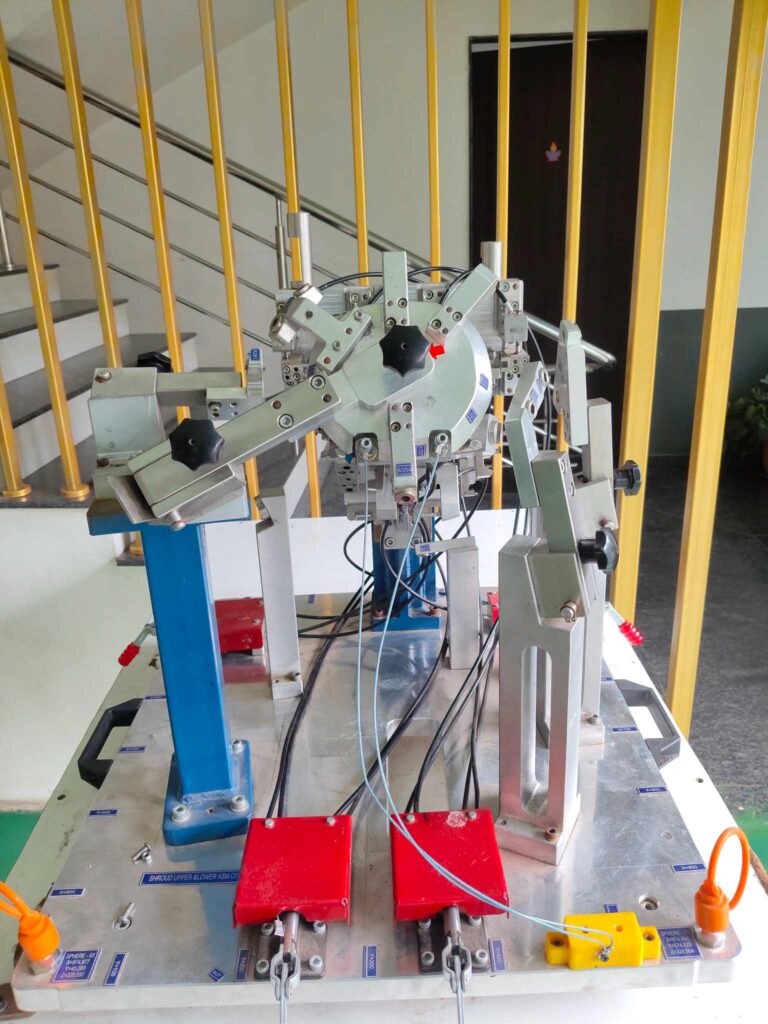

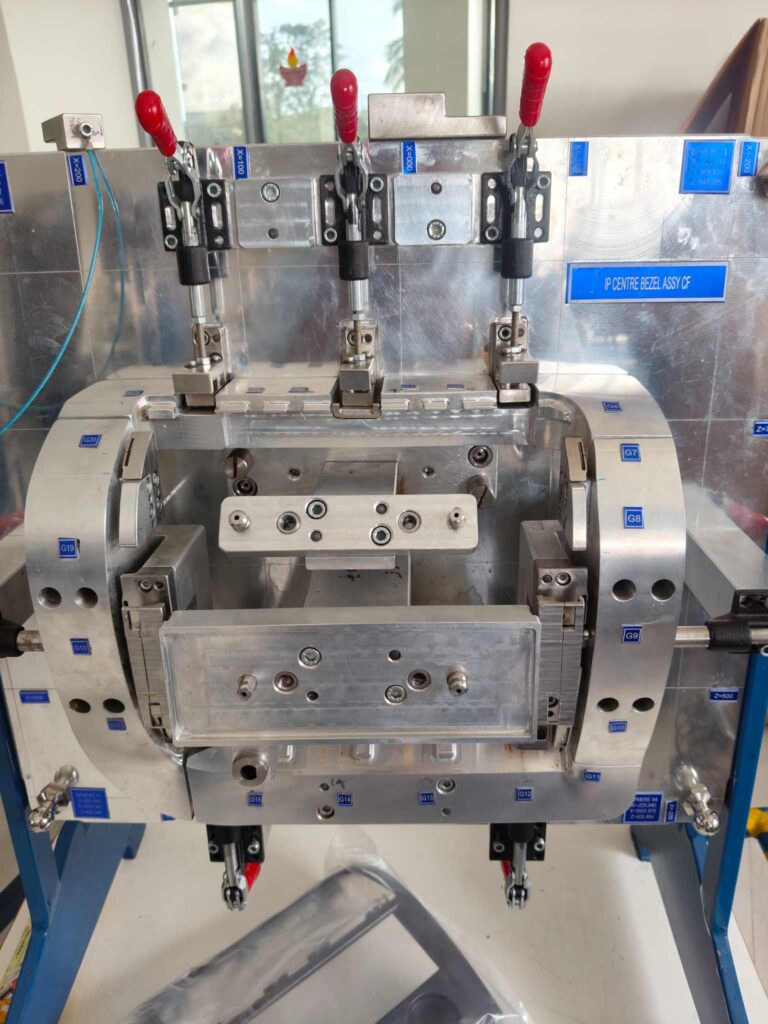

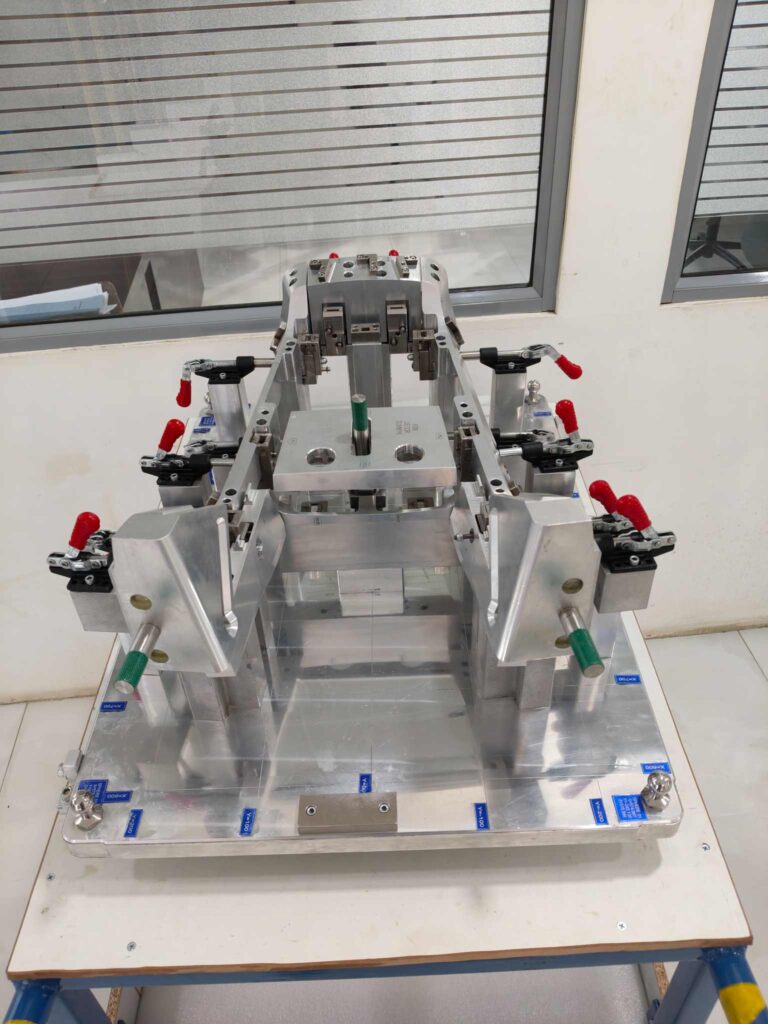

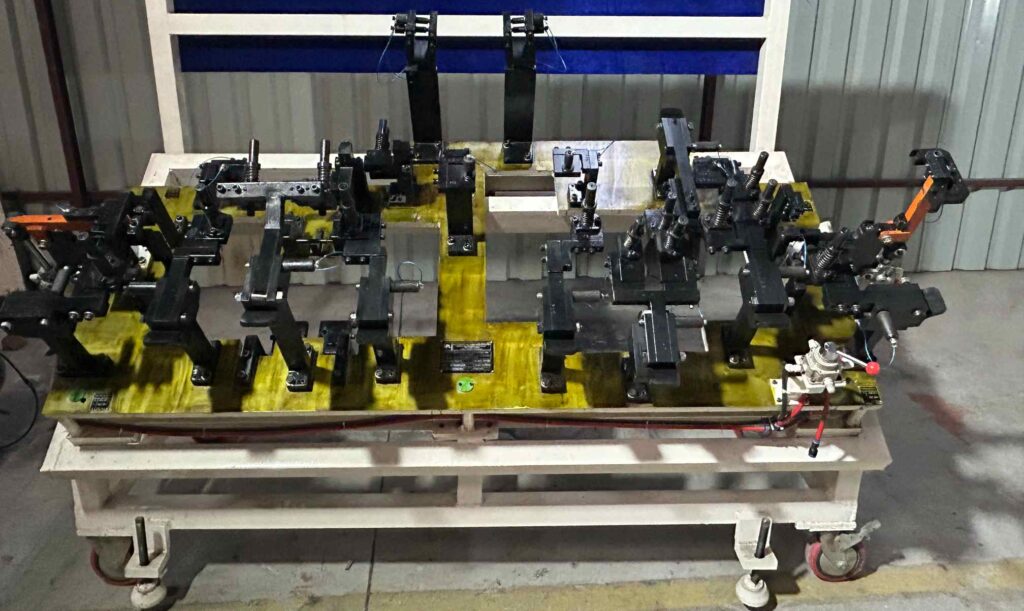

INTERIOR PARTS FIXTURES

Benefits:

- Improves inspection speed and accuracy compared to manual methods.

- Supports process optimization via detailed data for trend and root cause analysis.

- Can be combined with robotic automation for inline inspection.

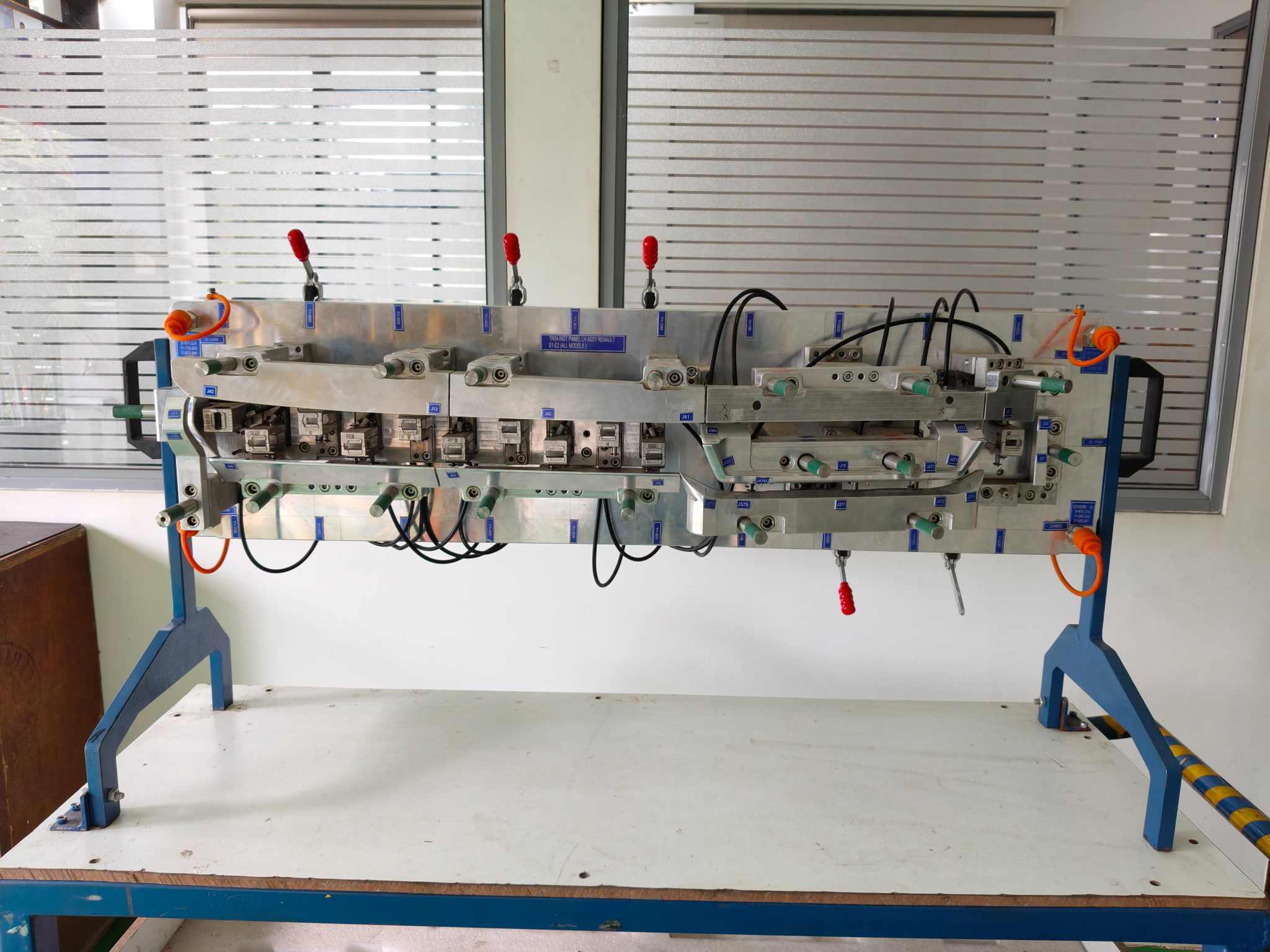

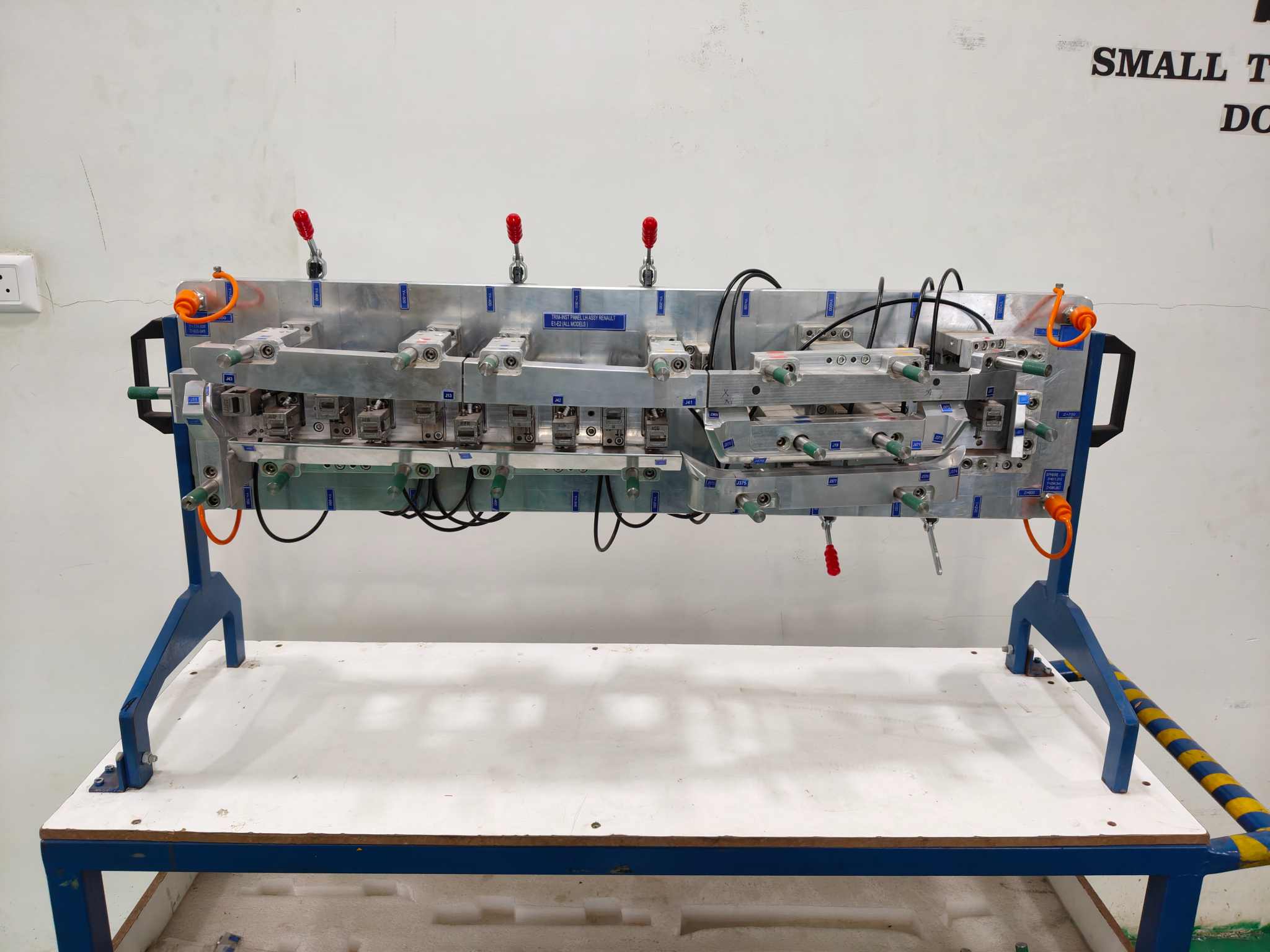

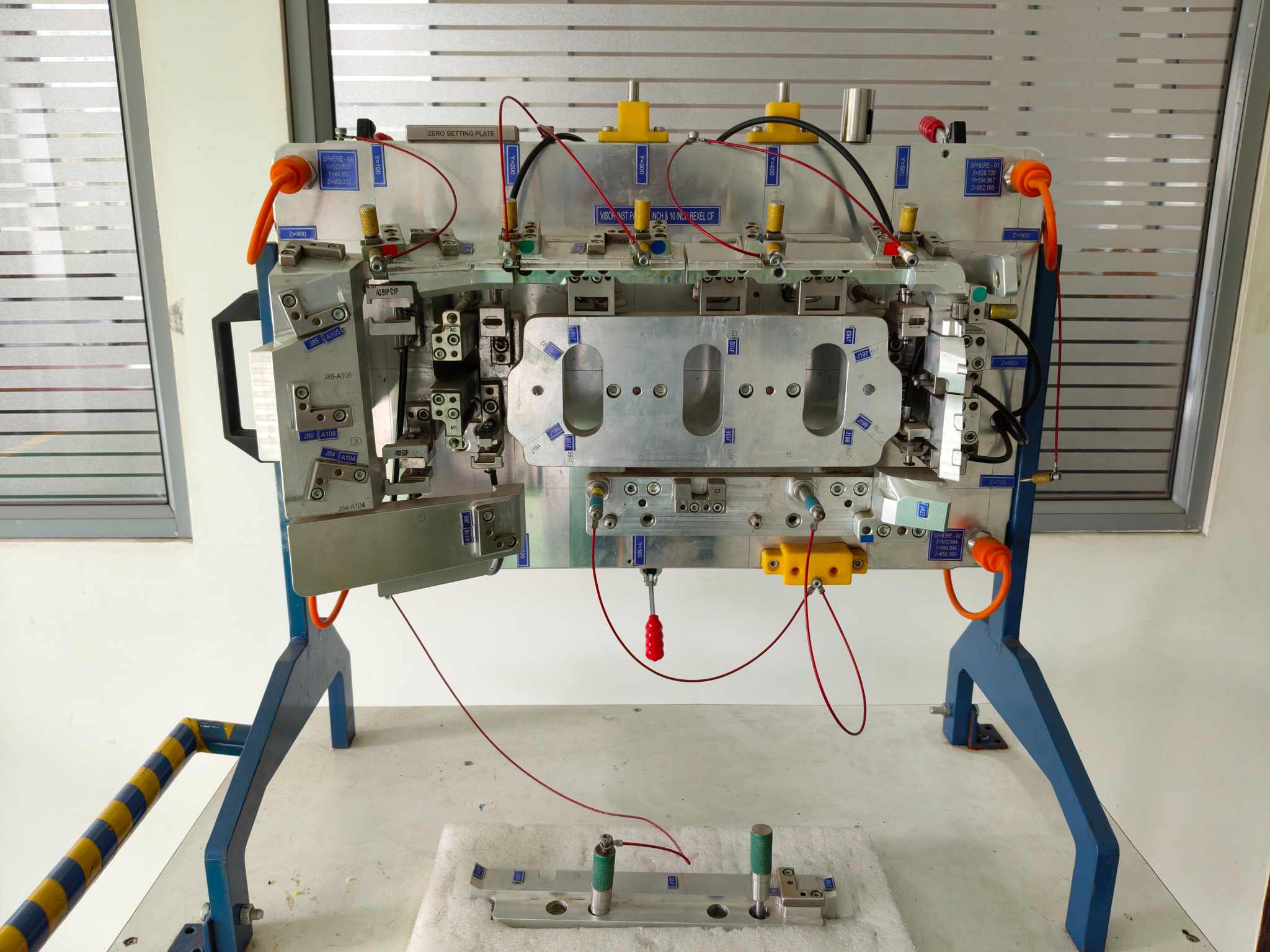

GAP AND FLUSH CHECKING FIXTURES

Gap and flush checking fixtures are precision tools used predominantly in the automotive industry to measure and ensure the proper alignment and spacing between adjacent parts or panels, like doors, hoods, bumpers, and body panels.

What Gap and Flush Checking Fixtures Do:

- Gap Measurement: Measures the perpendicular distance between two parts to ensure there is an appropriate and consistent clearance to prevent interference or friction.

- Flush Measurement: Measures how even or level two adjacent surfaces are with respect to each other, ensuring a smooth transition and aesthetics without steps or misalignment.

Importance in Automotive Manufacturing:

- Guarantees the quality of a vehicle’s fit and finish, which directly influences perceived value, aerodynamics, and noise levels.

- Prevents issues like wind noise, water leaks, and uneven door closing.

- Helps detect assembly defects early, saving costly rework and recalls.

Typical Features of Gap & Flush Checking Fixtures:

- Typically equipped with dial gauges or high-precision digital measurement devices for quick and accurate readings.

- Customizable to suit specific measurement points on various components.